Supporting copy for the Request Service

call out button.

Product Development / Design

Develop State-of-the-Art Products

Experimental Research, Analysis and Consulting, Design, Simulation, and Prototyping Capabilities

Working confidentially with you on many levels to enhance your products

- Increased system performance (heating/cooling capacity and efficiency)

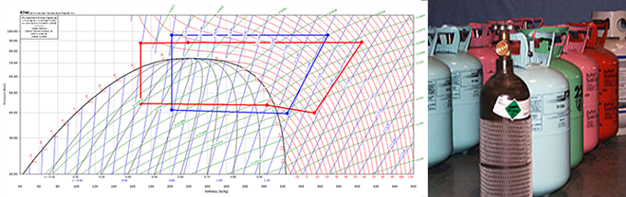

- Implementation of alternative refrigerants

- Lower GWP

- Enhanced performance

- Reduced flammability or toxicity

- Integration of novel technologies

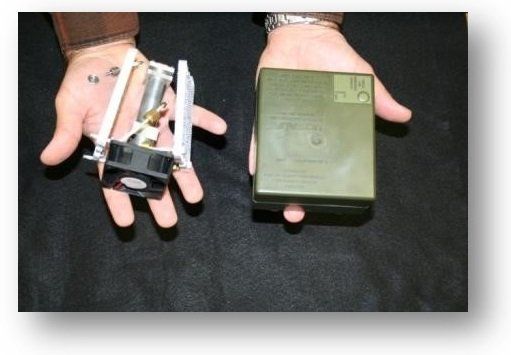

- Decreased weight and/or volume of system

- Overall refrigerant charge reduction

- Cost reduction

Experimental Research

Cutting-edge facilities to explore full systems, system components, and perform fundamental research

- Study of alternative natural and man-made refrigerants

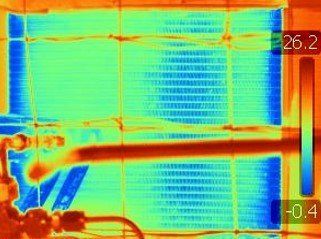

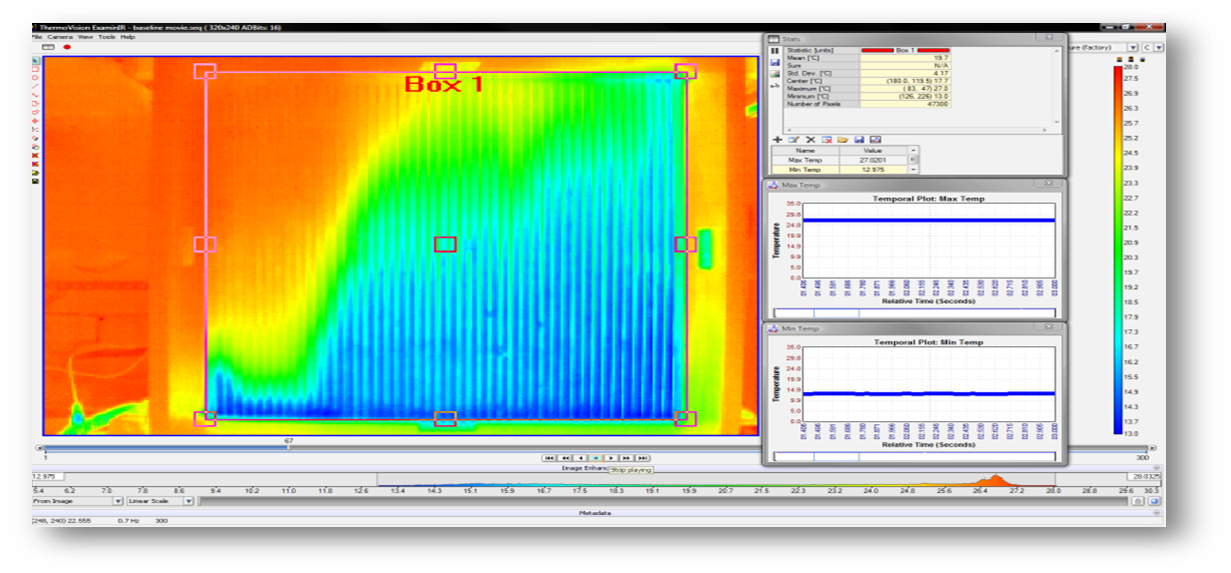

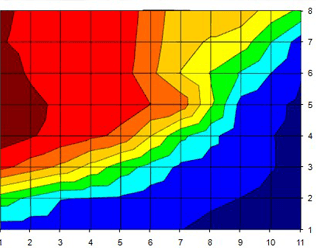

- Observation of distribution in heat exchangers and their headers

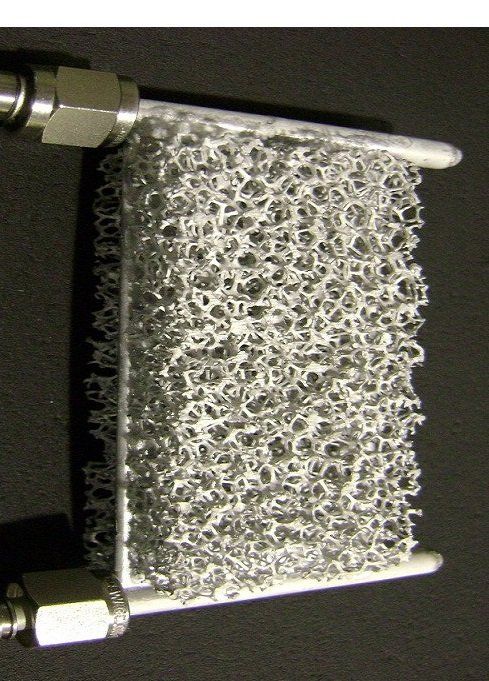

- Study of pressure drop, heat transfer, fluid mixture properties, two-phase fluid flows including those related to sub-millimeter length scales

- Analysis of efficiency and design of various flow separators

- Destructive and nondestructive durability testing

- Analysis of acoustic profiles from compressors and issues in heat exchangers and expansion devices including implementation of noise mitigation solutions

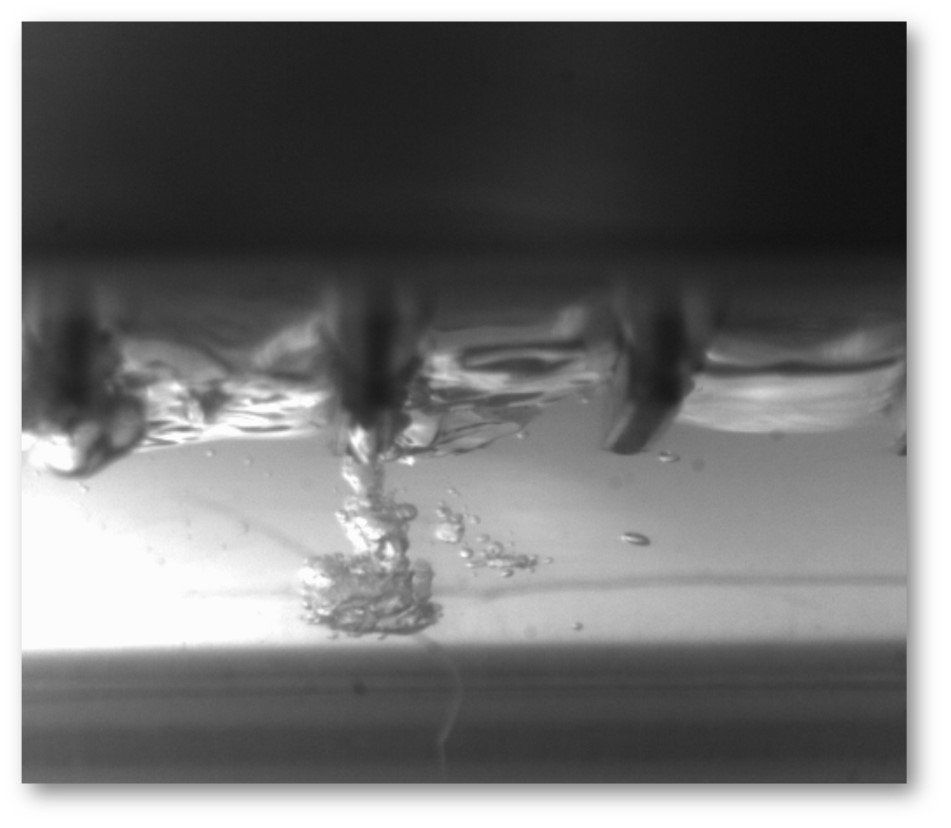

- Visualization of flow through novel expansion devices

- Visualization of compressor discharge

- Precise measurement of leakage rates of various refrigerants

Analysis and Consulting

- Accurate and repeatable experimental and simulation data

- Analysis and understanding behind the data

- Observations and results meaningful to your application

- Consulting services to help clients better understand their own experimental or performance data to provide valuable results and optimized designs

Product Design

- Expertise in novel product design

- Services for customers looking for innovative new products

- Consulting yielding improvements to existing products

- Design activities accompanied by prototyping services

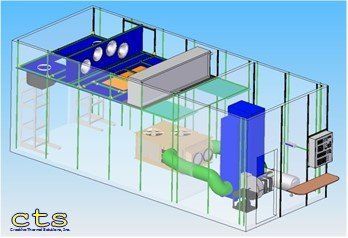

Simulation

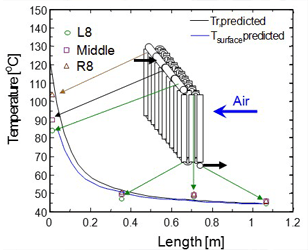

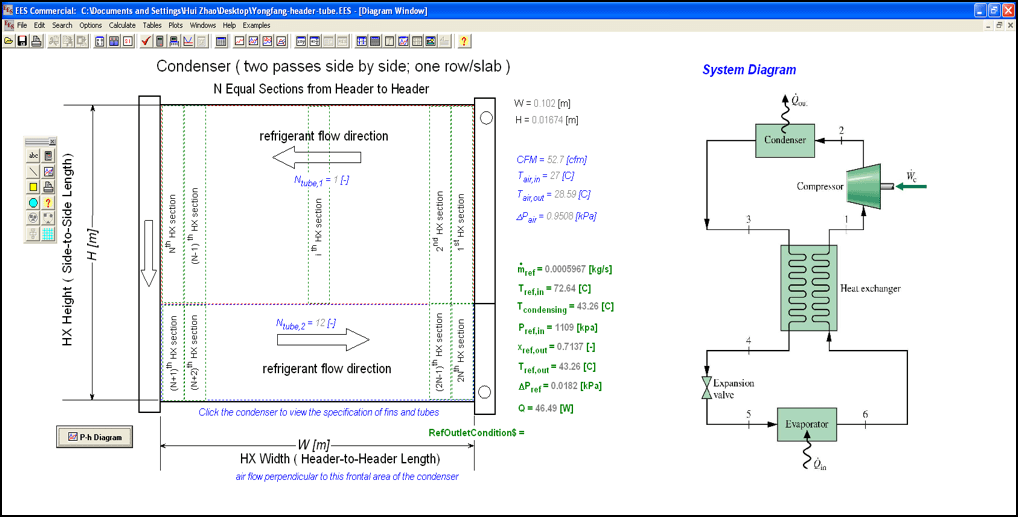

- Modular, In-house CTS written simulation models used to predict system and component performances

- Computation models are used in design as well as analysis and optimization of the elements under examination

- Predict system and component performances

- Models are validated and refined over a wide range of operating conditions

- Vast experimental database to validate simulation models

- Typical 5% accuracy match of dynamic and steady-state system response (ie cooling capacity and energy efficiency-COP) to experimental data

Prototyping

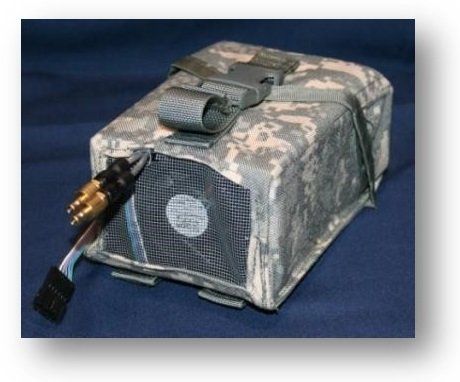

Custom fabricated solutions for any stage in the design, development, or product engineering processes

- Special units for in-house testing

- Custom components

- Turn-key, one-off products

- Demonstration models

About Our Business

CTS provides professional, confidential, consulting services by working with clients to serve their needs, research potential solutions, and successfully complete objectives. Whenever possible CTS tries to go beyond direct requests and provide additional insights that may be helpful for further improvements of the concept or the product.

Contact Our Team

Creative Thermal Solutions Inc

2209 North Willow Road

Urbana, IL 61802

217-344-7663

Privacy Policy

| Do Not Share My Information

| Conditions of Use

| Notice and Take Down Policy

| Website Accessibility Policy

© 2024

The content on this website is owned by us and our licensors. Do not copy any content (including images) without our consent.